Classification & Production Standards of Commercial Organic Fertilizer

Main types of commercial organic fertilizer can be classified into several types in accordance with its working conditions and nutrient content, including organic fertilizer, organic and inorganic fertilizer, and bio-organic fertilizer.

The Bio-organic Fertilizer refers to fertilizer produced by special and functional microorganism after harmless treatment and decomposition with composite organic materials.

The production standards of them are listed as follows:

|

Organic matter

(dry basis)

|

Total nutrient

(N, P2O5,

K2O, dry basis) |

Moisture

|

pH

|

Granularity (1- 4.75mm)

|

Others

|

|

|

Organic Fertilizer

|

≥30%

|

≥4%

|

≤20%

|

5.5-8.0.

|

If adding the active agents, it requires effective viable count

more than 20 million per gram and bacteria rate ≤20%. |

|

|

Organic & Inorganic Fertilizer

|

≥20%

|

≥15%

|

≤10%

|

5.5-8.0.

|

≥70%

|

|

|

Bio-organic Fertilizer

|

≥25%

|

≥6%

|

≤15%

|

5.5-8.5

|

The effective number of viable cells ≥ 20 million per gram and bacteria rate ≤20%.

|

(Data sources: China’s Ministry of Agriculture)

Notice: the production standards may vary in different areas/countries. Before staring commercial organic fertilizer production, investors should figure out the production standard satisfying local essential needs.

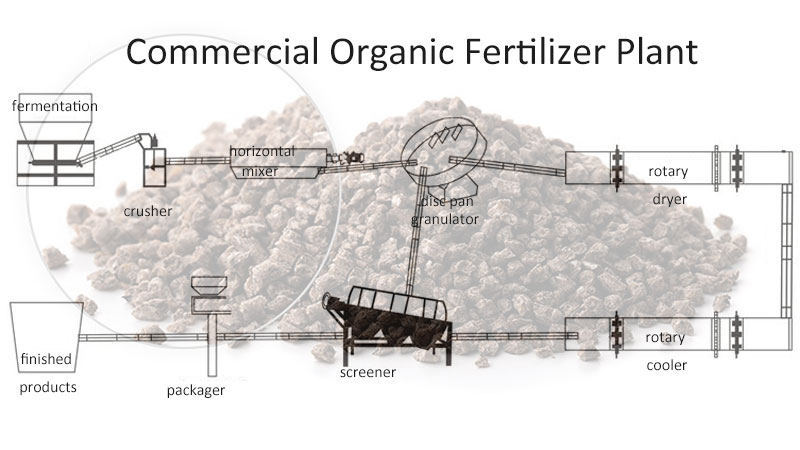

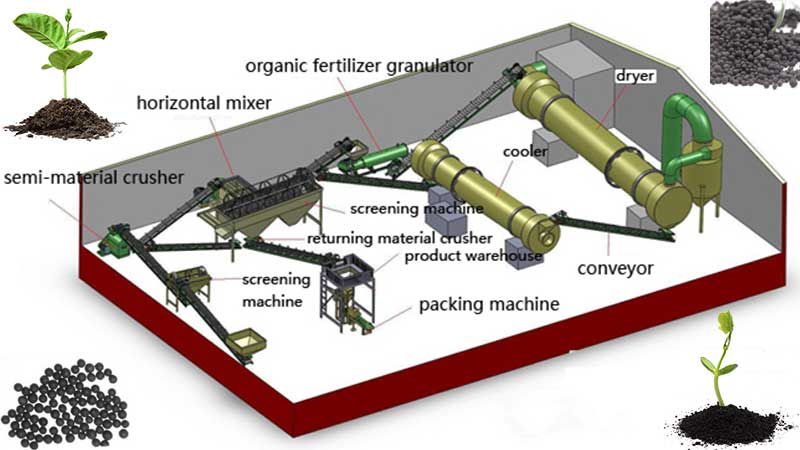

Commonly Used Composting & Granulation Machines in Commercial Organic Fertilizer Production

It is essential for manufacturers to choose the right fertilizer machines. There are many factors affecting the quality of commercial organic fertilizer, equipment being the most important one.

Commercial organic fertilizer production mainly includes 2 processes. One is harmless organic waste treatment process: compost-making materials decomposition and fermentation. The main raw materials for commercial organic fertilizer production includes animal manure, municipal sewage sludge, garbage, candy pomace, crop stalks, paper filter mud, food and fermentation organic industrial waste, etc. The heat produced by thermophilic bacteria kills pathogenic microorganisms, viruses, bacteria, protozoa, worms and eggs that may inhabit wastes.

The other part is the granulation process of composting material. Benefits of organics granulation is to make organic fertilizer have good commercial properties, stable nutrient content and fertilizer efficiency for further storage, transportation and sale.

It usually adopts aerobic fermentation as the core of compact treatment in commercial organic fertilizer industrial production. The process consists of solid-liquid separation, material pre-treatment, fermentation, turning and decomposition. Studies have shown that the essence of the fermentation process is microbial decomposition of organic matter, wherein the amount of gas, temperature, humidity, and C/N are the main fermentation parameters, so the key technology of the regulation is to create a suitable environment for the aerobic microorganisms. In the retting process, heap mild pH value rising leads to nitrogen volatilization losses. Reducing nitrogen loss and preventing excessive organic matter decomposition of organic fertilizer are the keys to improve the organic fertilizer quality. The above problems can be solved by improving material pre-treatment, adjusting C/N, moisture, pH, and controlling temperature and fermentation time.

◇ Fermented organic material granulation

Fermented organic materials are characterized by coarse texture, poor adhesion and granulating difficulty. It has been bottleneck in organic fertilizer production for a long time. Organic fertilizer granulation can be in extrusion granulator organic production line and disc granulation organic fertilizer production line. Recently, organic fertilizer production can be processing in new type fertilizer granulator production line and rotary fertilizer granulator production line.

Extrusion granulation: composting material with an appropriate amount of inorganic fertilizer is extruded by flat die extrusion granulator, and then

Disc granulation: Almost all organic materials can be granulated with a disc fertilizer granulation technology. After material drying and finely pulverized with an adequate amount of fertilizer, materials are sending into the disc granulator machine. The materials are mixed and bonded by humidifier spraying. With the rotation of the disc granulator, materials are produced to granules, and then it is sieved and dried again. Finally, it can be bagging. This kind of organic fertilizer production has modest production power, needs small power. The granules are in size of round shape. Before granulation, organic fertilizer raw materials need to be dried and crushed.

New type granulation: new type organic fertilizer granulator is advanced fertilizer granulator machine. It can be used for all kinds of organic matters. There is no drying and crushing in organic fertilizer production. Mix organic raw materials in the machine, and then it can produce spherical granules. The organic matter content can reach to 100%, which is really pure organic material granulation. There is no need to dry fermented organic materials. The water content of organic raw materials can be 20-40%. The granulation rate is over 95%.